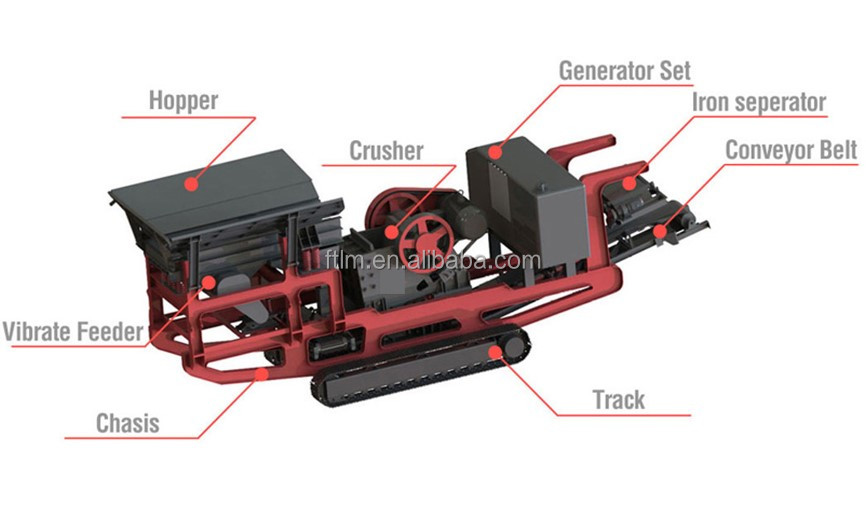

crawler mobile crusher

The Track-Mounted Mobile Crushing Plant is an advanced, fully integrated crushing and screening solution characterized by its exceptional mobility and efficiency. Mounted on a powerful crawler chassis, it can self-propel directly to the source of the material—be it a quarry, mine, or construction site—significantly reducing material transport costs and setup time compared to fixed plants. Featuring high-performance crushing components, intelligent controls, and environmentally conscious design (including dust and noise reduction), this machine provides a flexible, high-capacity, and cost-effective alternative for producing high-quality aggregates and recycling construction and demolition waste.

Description of Track-Mounted Mobile Crushing Plant

The Track-Mounted Mobile Crushing Plant is a fully mobile crushing and screening system that integrates core equipment like the crusher, feeder, and vibrating screen onto a rugged, self-propelled crawler chassis.

It is primarily designed for aggregate production, construction waste recycling, mining operations, and road construction—any application that requires frequent relocation or where the working site is constantly moving. The goal of this machine is to replace traditional stationary crushing systems, allowing the crusher to go directly to where the material is located.

Certainly! Here is the description, features, and other related information for the Crawler Mining Crushing Crusher (also commonly referred to as a Track-Mounted Mobile Crushing Plant).

Description of Track-Mounted Mobile Crushing Plant

Working Principle

The Track-Mounted Mobile Crushing Plant's working principle relies on its high integration and exceptional mobility: it uses a hydraulic-driven crawler chassis to self-propel to the processing site. The material is first received by the feeder and uniformly delivered to the core crusher (such as a Jaw, Cone, or Impact crusher), where it is broken down through compression or impact. The crushed material is then conveyed to the vibrating screen for sizing. Acceptable finished products are discharged, while oversized material is efficiently routed back to the crusher via a return system, completing a highly effective closed-circuit cycle to ensure continuous, full-process operation from raw material to final aggregate product, all on a single mobile platform.

Main characteristics

Track-mounted mobile crushing plants are typically classified based on the core crusher unit they carry:

1.Track-Mounted Mobile Jaw Crusher: Generally used for primary crushing of large, hard materials.

2.Track-Mounted Mobile Cone Crusher: Typically used for secondary, tertiary, and fine crushing to produce high-quality aggregates.

3.Track-Mounted Mobile Impact Crusher: Suitable for crushing medium-hardness materials, known for producing a good cubical particle shape and high reduction ratio.

4.Track-Mounted Mobile Screening Plant: Focuses primarily on screening and classifying materials.

Application Fields

1.Mining Operations: Initial crushing of run-of-mine ore right at the mining face.

2.Aggregate Production: Manufacturing various sizes of aggregates for concrete, asphalt, etc.

3.Construction & Demolition (C&D) Waste Processing: Crushing and recycling concrete blocks, bricks, asphalt, and other solid waste.

4.Infrastructure Projects: On-site stone processing for roads, bridges, and hydraulic engineering construction.