Mineral Rock Wool Poduction Line

Rock Wool is mainly used for fireproofing and sound absorption of partition walls and curtain walls, thermal insulation of roofs,retaining structures and geothermal systems as well as thermal insulation and fireproofing of industrial kilns, ovens, large sized tanks and vessels, etc.

Rock Wool is mainly used for fireproofing and sound absorption of partition walls and curtain walls, thermal insulation of roofs,retaining structures and geothermal systems as well as thermal insulation and fireproofing of industrial kilns, ovens, large sized tanks and vessels, etc

it is made from natural basalt, by high temperature melting, through the high-speed centrifuge equipment made of artificial inorganic fibers, add the special adhesives and dustproof oil, then after heating curing, make various specifications, different requirements of the rock wool insulating board.

Rock wool boards have higher strength and better elasticity. The folded rock wool board with certain compression resistance has greater drawing strength, and it does not tend to peel off and the durability has greatly improved.

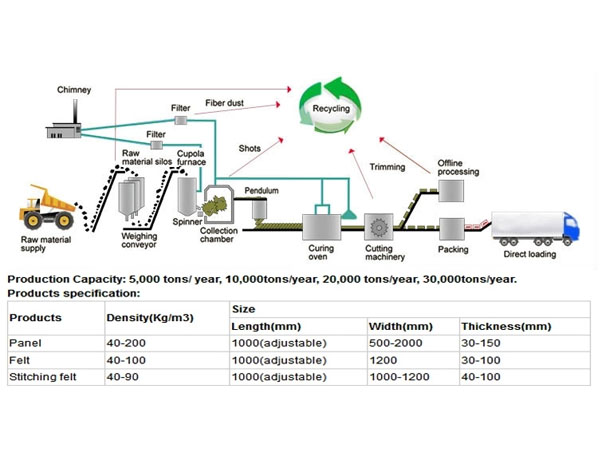

Main Process of Rock Wool Production Line

| 1 | Raw material system | 1)Feeding system 2) Automatic proportioning machine |

| 2 | Melting system | 1) Furnace platform 2)Cupola furnace |

| 3 | Wool making system | 1) High speed centrifuge |

| 4 | Rock wool resin-spraying system | 1)Laser tracking system of lava |

| 5 | Wool collecting and allocation system & | 1)Wool collector and Pendulum wool allocation machine |

| 6 | Curing oven explosion-proof system | 1) Natural gas inspect system 2)Explosion-proof fan |

| 7 | Cutting system | 1)Cooling conveyor2) Cooling fan 3) Thickness saw |

| 8 | Dust-removing system of cutting part | 1)Bag-type dust filter |

| 9 | Curing oven hot blast system | 1) Heat-resisting fan |

| 10 | Scrap recycling machine | 1)Crusher |